- Product

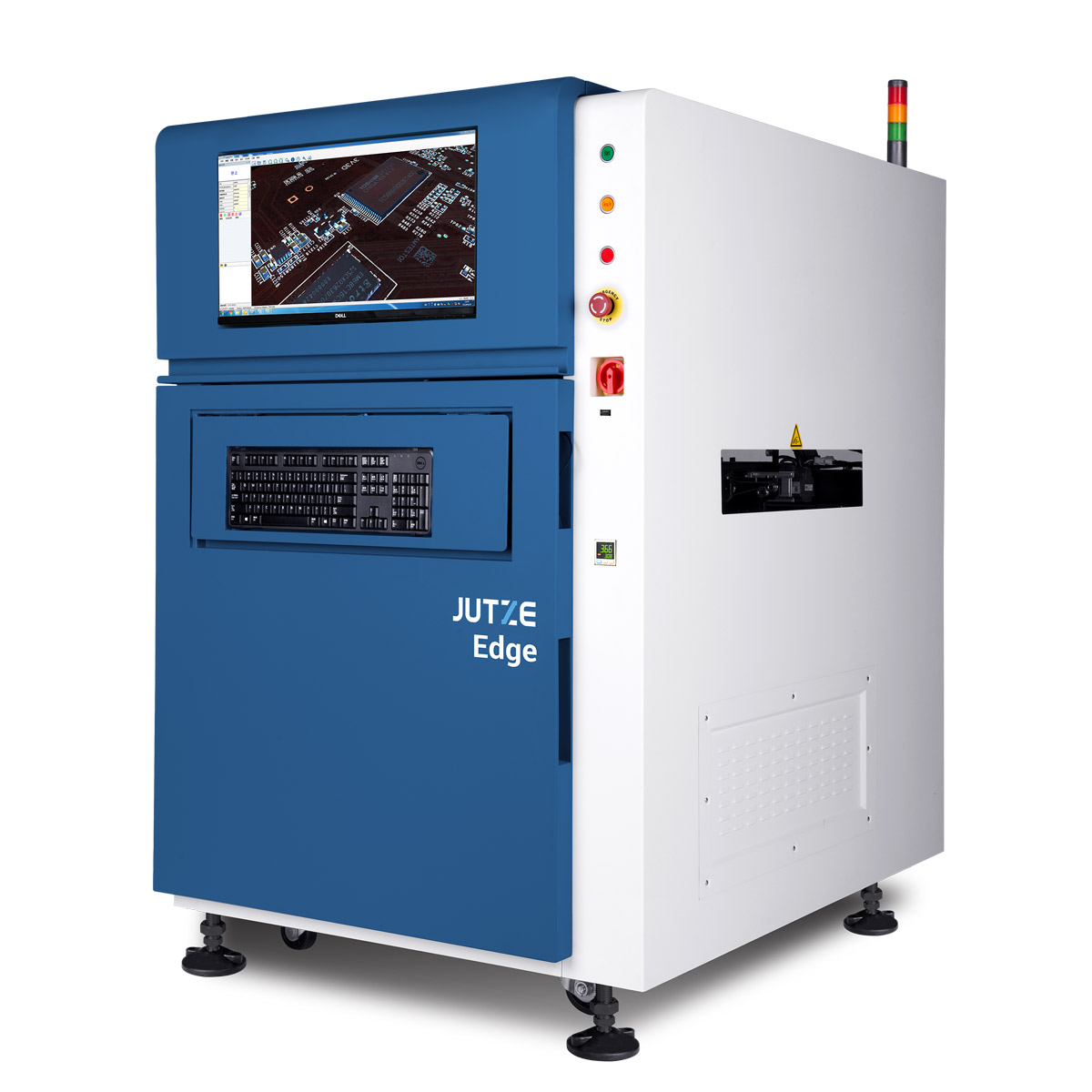

2D AOI

High speed, high precision

- Twins

- LI-6000D

- LI-5000

- LI-3000DP

- MI-3000

- XI-2000

- LD-5000

- MD-2000

- XD-2000

Laser marking equipment

machine vision technology ensures the accuracy and speed of marking

- LMUV-1000

- Spark-CD

- LMF-2000

- LMC-3000

- SHINE-C1

- SHINE-F1

Optional accessories

AOI corresponding accessories

- Real-time remote debugging

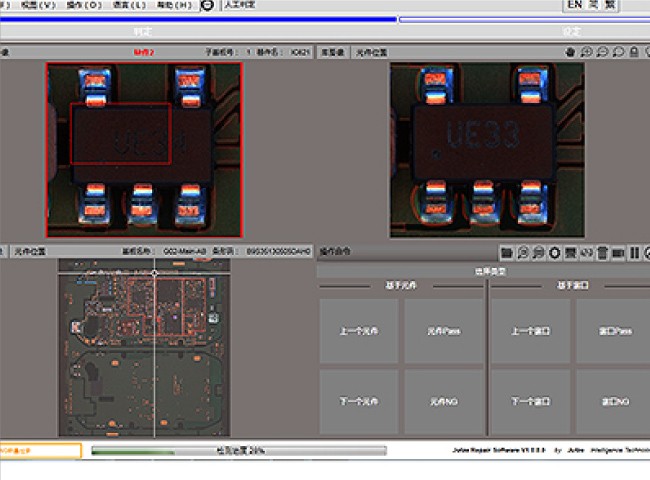

- Repair terminal

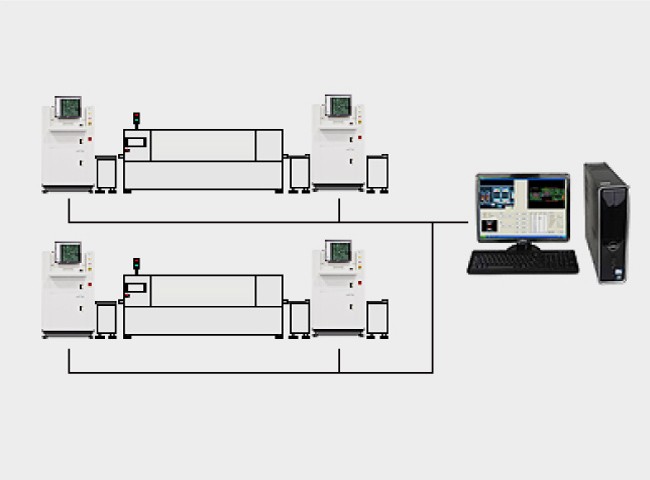

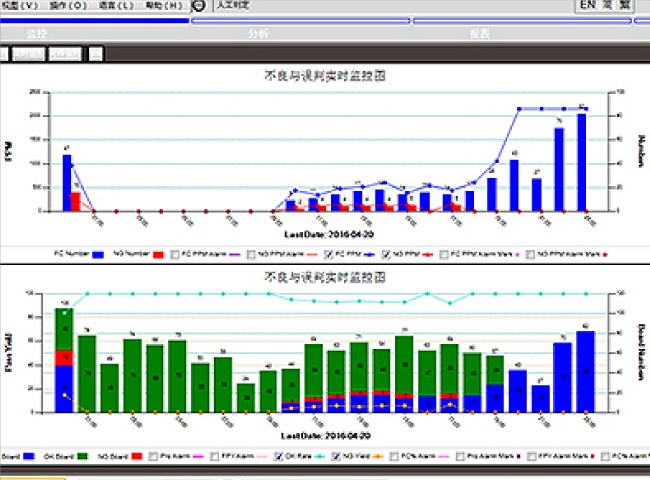

- Centralized management

- SPC

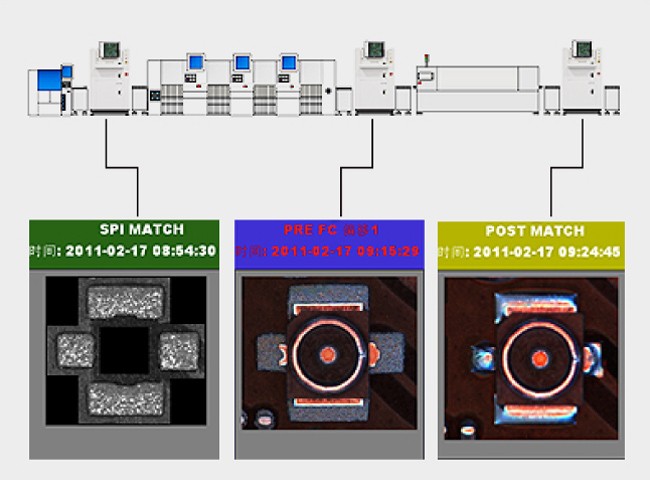

- Three-point comparative analysis

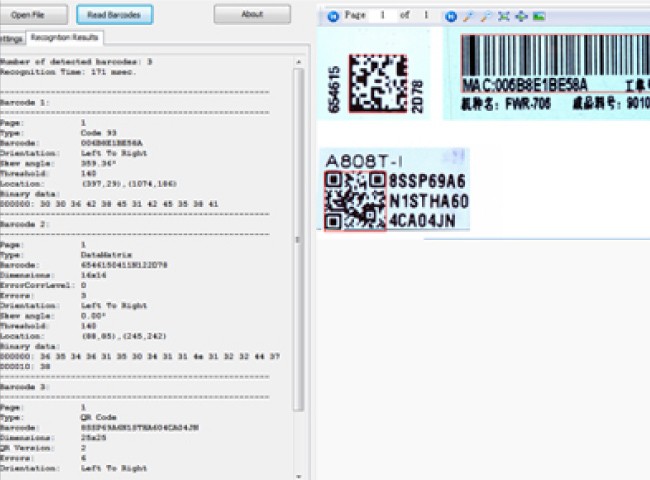

- Bar code

- Industry Application

- Investor Relations

- News

- Recruitment

Contact us

Contact us

沪公网安备 31011202003871号

沪公网安备 31011202003871号